The COMES group has a robust experimental infrastructure distributed across the campuses of

Ciudad Real

and

Toledo

, equipped to support cutting-edge projects in material characterization, structural analysis, computational simulation, and advanced manufacturing. The laboratories are designed to integrate both fundamental and applied research capabilities and are available for academic projects as well as industry collaborations.

-

Continuum Mechanics and Structures Laboratories (ETSII+INAIA)

-

Materials Science and Engineering Laboratories (ETSII+INAIA)

-

Composite Materials Manufacturing and Characterization Laboratory (INEI)

Below is a list of the COMES group's equipment:

Testing and Characterization

-

Mechanical Testing

-

MICROTEST triaxial machine (50 kN per axis) with independent actuators for uniaxial, biaxial and triaxial tests

-

MICROTEST universal testing machines (100 kN and 200 kN)

-

Instron 5969 machine with 1 kN and 50 kN load cells and tooling for shear, bending, etc.

-

Instron CEAST 9340 drop weight impact tower

-

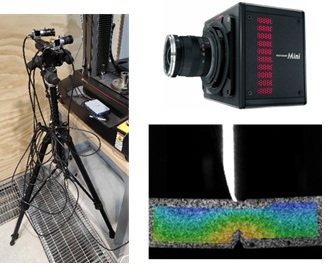

Digital Image Correlation (DIC)

-

2D and 3D systems for strain capture and analysis

-

High-speed camera Photron Mini AX50

-

VIC Snap/2D/3D software, LaVision DaVis

-

Strain Measurement

-

Extensometers, deflectometers, strain gauge boxes (KYOWA), video extensometer, LVDT

-

Non-destructive Testing

-

Phased-array system (OmniScan MX2) and Olympus 38DLPLUS thickness gauge

Materials Characterization

-

Mechanical Characterization

-

Charpy pendulums (300 J and 25 J)

-

PIN-ON-DISK MT/60 tribometer (high-temperature testing)

-

Hardness and microhardness testers (Rockwell, Brinell, Vickers, Knoop, Shore)

-

Physical Characterization

-

Accupyc II 1340 helium pycnometer

-

Precision balances and measurement set based on Archimedes' principle

-

MFI-500/AP-400C melt flow index tester

-

TGA/DSC thermobalance NETZSCH STA 449 C

-

Access to HRSEM, XRD and elemental analysis C/S/O

-

Metallographic Preparation

-

Secotom-20 cutter, CitoPress-5 press, Tegramin-20 grinder, LectroPol-5 polisher

-

Macro and Microstructural Characterization

-

Microscopes: SZX10, Olympus GX53, Leica DM-IRM, SEM JEOL JSM-6610LV + EDS

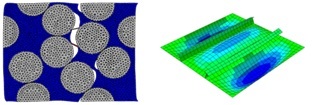

Modelling and Simulation

-

FEM software licenses: ABAQUS®, ANSYS®, ADINA

-

Workstation W20P: computing server with 24 cores, 128 GB RAM, NVIDIA Quadro GPU

Manufacturing, Processing and Thermal Treatments

- Powder Metallurgy

- Planetary ball mill PM100 (RETSCH)

- Uniaxial press (100 kN)

- High-temperature tube furnaces: Nabertherm (1700 °C) and Carbolite (1500 °C)

- Additive Manufacturing

- Machining

- Access to CNC machines for specimen preparation

- Thermal Treatments

- Muffle furnaces up to 1100 °C with atmosphere control

- Edwards turbomolecular vacuum station (down to 5×10⁻⁸ mbar)

- Solar Thermal Processing

- Fresnel lens (900 mm) and reaction chamber with atmosphere control

- Data acquisition system, solar tracker and pyrheliometer